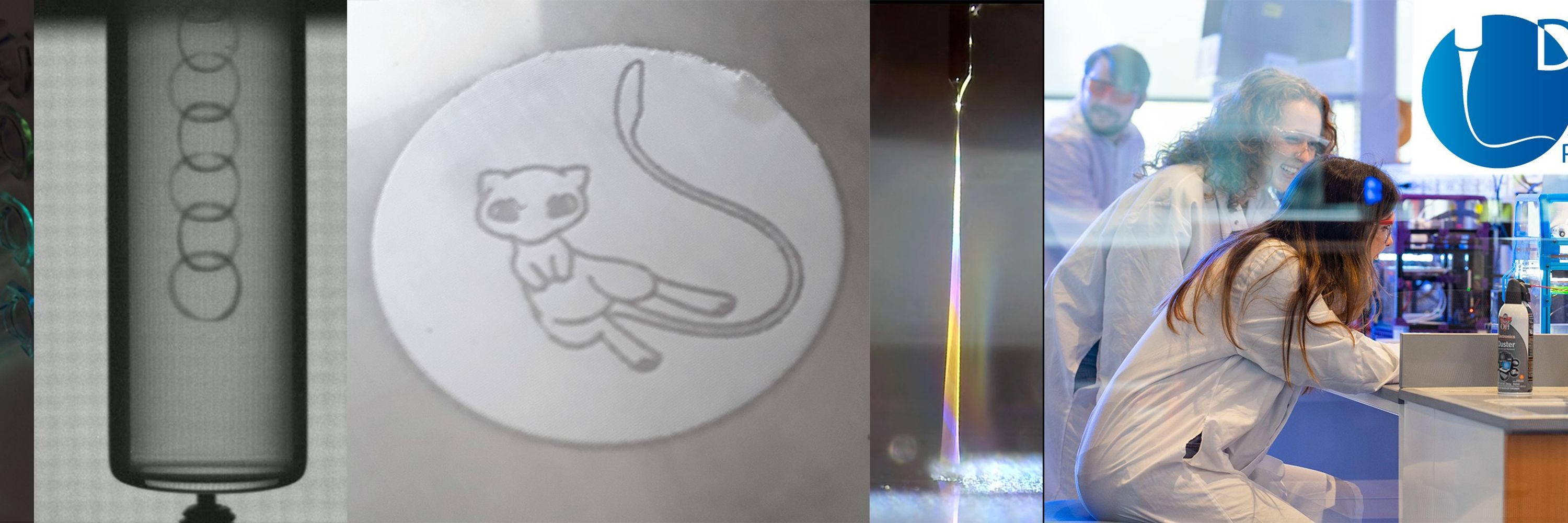

With MEW fibers providing a scaffold for the fibroblasts + an electrospun membrane as an artificial basement membrane, a high quality full-thickness model was created.

With MEW fibers providing a scaffold for the fibroblasts + an electrospun membrane as an artificial basement membrane, a high quality full-thickness model was created.