Paul Dalton

@daltonlab.bsky.social

Associate Professor at the Knight Campus, Oregon. 3D printing fanboy; tissue engineer & scaffold designer, teacher, entrepeneur, lover of the outdoors, melt electrowriting inventor. #Biofabrication, #MEW, #3Dprinting, #bioengineering, #meltelectrowriting

Cell Culture Research Engineer

Great opportunity for melt electrowriting scaffold users. In one of the most beautiful regions of the world.

www.linkedin.com/jobs/view/43...

www.VivoTex.com

Great opportunity for melt electrowriting scaffold users. In one of the most beautiful regions of the world.

www.linkedin.com/jobs/view/43...

www.VivoTex.com

November 5, 2025 at 3:04 AM

Cell Culture Research Engineer

Great opportunity for melt electrowriting scaffold users. In one of the most beautiful regions of the world.

www.linkedin.com/jobs/view/43...

www.VivoTex.com

Great opportunity for melt electrowriting scaffold users. In one of the most beautiful regions of the world.

www.linkedin.com/jobs/view/43...

www.VivoTex.com

Reposted by Paul Dalton

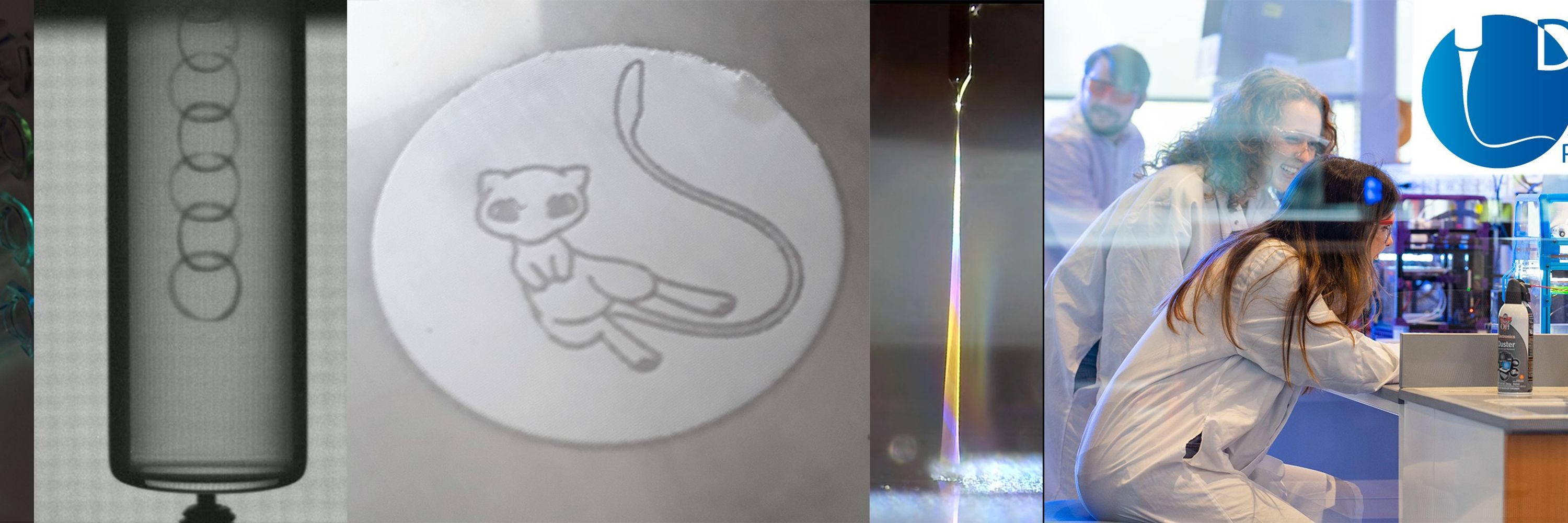

Recently, we published a very nice paper with the team of @daltonlab.bsky.social on volumetric 3D printing. Check out the videos too! Now I brewed the corresponding paperbeer. A Westcoast IPA called Volumetric Vision. It turned out quite alright!

advanced.onlinelibrary.wiley.com/doi/abs/10.1...

advanced.onlinelibrary.wiley.com/doi/abs/10.1...

April 30, 2025 at 6:27 PM

Recently, we published a very nice paper with the team of @daltonlab.bsky.social on volumetric 3D printing. Check out the videos too! Now I brewed the corresponding paperbeer. A Westcoast IPA called Volumetric Vision. It turned out quite alright!

advanced.onlinelibrary.wiley.com/doi/abs/10.1...

advanced.onlinelibrary.wiley.com/doi/abs/10.1...

Reposted by Paul Dalton

New publication from the @daltonlab.bsky.social lab, led by Patrick Hall optimizes a unique 3-D manufacturing technique, called volumetric additive manufacturing (VAM) – which has potential applications for implants, hydrogels, and more.

Read more: knightcampus.uoregon.edu/printing-fut...

Read more: knightcampus.uoregon.edu/printing-fut...

February 17, 2025 at 8:16 PM

New publication from the @daltonlab.bsky.social lab, led by Patrick Hall optimizes a unique 3-D manufacturing technique, called volumetric additive manufacturing (VAM) – which has potential applications for implants, hydrogels, and more.

Read more: knightcampus.uoregon.edu/printing-fut...

Read more: knightcampus.uoregon.edu/printing-fut...

Have been a fanboy of volumetric additive manufacturing (VAM), so it is great to develop and publish this paper doi.org/10.1002/admt.... Since VAM can burn through bioresins, we wanted to develop a low-cost, easy to make formulation with good resolutions and visualization. Enjoy!

December 24, 2024 at 4:39 PM

Have been a fanboy of volumetric additive manufacturing (VAM), so it is great to develop and publish this paper doi.org/10.1002/admt.... Since VAM can burn through bioresins, we wanted to develop a low-cost, easy to make formulation with good resolutions and visualization. Enjoy!

With a bluesky account, here is a blast from the past and a test of threads. doi.org/10.1002/adma... changes a fundamental which unlocks geometric freedom for melt electrowriting (MEW). Instead of direct-writing fibers directly on top of each other, the fiber-on-fiber position can be controlled....

November 30, 2024 at 3:27 AM

With a bluesky account, here is a blast from the past and a test of threads. doi.org/10.1002/adma... changes a fundamental which unlocks geometric freedom for melt electrowriting (MEW). Instead of direct-writing fibers directly on top of each other, the fiber-on-fiber position can be controlled....

A classic melt electrowriting (MEW) video. With a nozzle-collector gap of 3.5 mm, a polycaprolactone melt is extruded to a 5.75kV charged 22G nozzle, thinning out into a fine microfiber. The jet speed is 260mm/min and although the collector speed increases, it never breaks. doi.org/10.1002/admt...

November 20, 2024 at 3:00 PM

A classic melt electrowriting (MEW) video. With a nozzle-collector gap of 3.5 mm, a polycaprolactone melt is extruded to a 5.75kV charged 22G nozzle, thinning out into a fine microfiber. The jet speed is 260mm/min and although the collector speed increases, it never breaks. doi.org/10.1002/admt...

We worked on "taming the jet" for some years, and here is an important milestone in MEW development. Now shown proof of principle, how can we adopt this across all systems, especially the low-cost #MEWron to make them even more powerful!

techxplore.com/news/2024-11...

www.nature.com/articles/s44...

techxplore.com/news/2024-11...

www.nature.com/articles/s44...

Towards industry-ready additive manufacturing: AI-enabled closed-loop control for 3D melt electrowriting - Communications Engineering

Pawel Mieszczanek and colleagues design a machine learning-based approach to improve 3D printing processes based on melt electrowriting. They present a closed-loop control framework that is based on d...

www.nature.com

November 20, 2024 at 1:19 PM

We worked on "taming the jet" for some years, and here is an important milestone in MEW development. Now shown proof of principle, how can we adopt this across all systems, especially the low-cost #MEWron to make them even more powerful!

techxplore.com/news/2024-11...

www.nature.com/articles/s44...

techxplore.com/news/2024-11...

www.nature.com/articles/s44...

This is an artifical full-thickness skin that was made in partnership with L'Oreal, published in 2024 here: doi.org/10.1002/adfm...

With MEW fibers providing a scaffold for the fibroblasts + an electrospun membrane as an artificial basement membrane, a high quality full-thickness model was created.

With MEW fibers providing a scaffold for the fibroblasts + an electrospun membrane as an artificial basement membrane, a high quality full-thickness model was created.

November 18, 2024 at 12:54 AM

This is an artifical full-thickness skin that was made in partnership with L'Oreal, published in 2024 here: doi.org/10.1002/adfm...

With MEW fibers providing a scaffold for the fibroblasts + an electrospun membrane as an artificial basement membrane, a high quality full-thickness model was created.

With MEW fibers providing a scaffold for the fibroblasts + an electrospun membrane as an artificial basement membrane, a high quality full-thickness model was created.

My first share comes from alumni Dr Moatazbellah Youssef, who beautifully shows the printing resolutions of MEW. Corbion PC-12, 2.5 micron fibers, 50 micron spacing. I love this image as it shows the difference in scale - the 100 micron scale bar is about as small as one can get from melt extrusion.

November 18, 2024 at 12:29 AM

My first share comes from alumni Dr Moatazbellah Youssef, who beautifully shows the printing resolutions of MEW. Corbion PC-12, 2.5 micron fibers, 50 micron spacing. I love this image as it shows the difference in scale - the 100 micron scale bar is about as small as one can get from melt extrusion.

November 18, 2024 at 12:26 AM

Let's start this account with some science from a fanboy - we try to increase volumetric printing resolution AND improve the cost. We did both and now have some PEGDA resins that cost 2c/print. In revision but hopefully soon to be published!

November 17, 2024 at 5:30 PM

Let's start this account with some science from a fanboy - we try to increase volumetric printing resolution AND improve the cost. We did both and now have some PEGDA resins that cost 2c/print. In revision but hopefully soon to be published!