Working on creating in-depth and up-to-date documentation on crafting standards/techniques and material sourcing for full contact weapons for foamfighting sports: https://wiki.whackerdashery.com

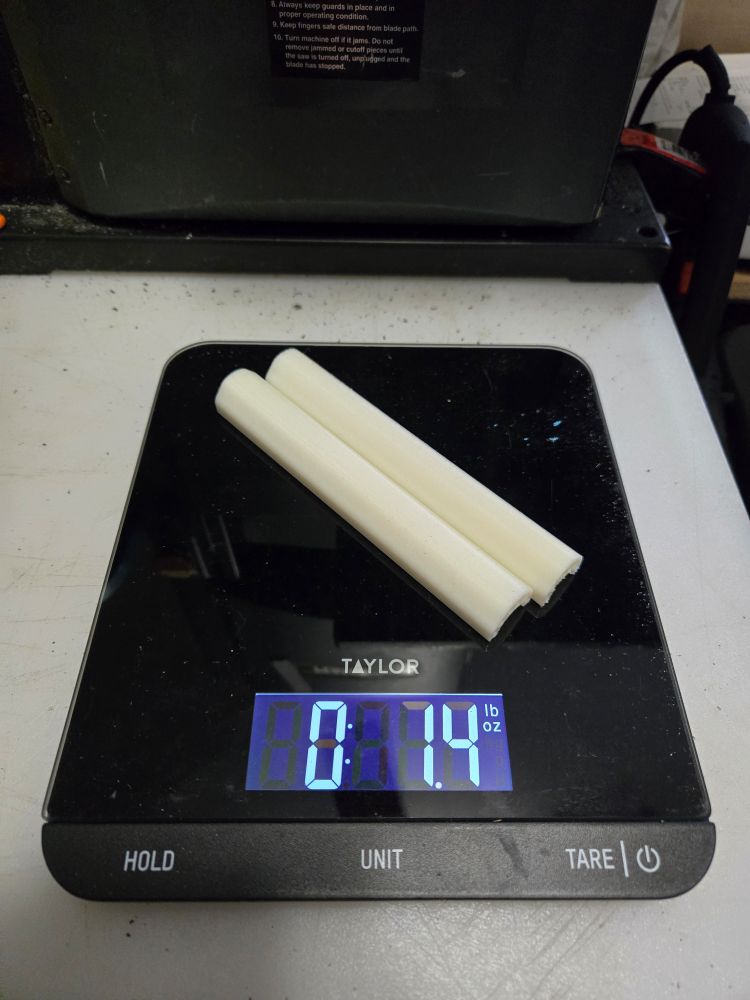

Built on the new High Modulus (390) 14\*10 spec. The test of 230 Modulus for this spec/length/application had too much flex and is getting cut down. Only added 1.5 oz over the previous build.

(next to 8.5' glaive)

#Foamsmithing

Built on the new High Modulus (390) 14\*10 spec. The test of 230 Modulus for this spec/length/application had too much flex and is getting cut down. Only added 1.5 oz over the previous build.

(next to 8.5' glaive)

#Foamsmithing

Just under the line for tariffs taking effect, too. Supplier got hit with a surprise retroactive upcharge of $100 on the shipment from the freight cost (not tariffs) going up thanks to impending tariffs. *sigh*

Just under the line for tariffs taking effect, too. Supplier got hit with a surprise retroactive upcharge of $100 on the shipment from the freight cost (not tariffs) going up thanks to impending tariffs. *sigh*

macuahuitl

macuahuitl

#Foamsmithing

#Foamsmithing

Foamdom is now The Whackerdashery and the docs site has been renamed to Whackipedia.

www.whackerdashery.com

wiki.whackerdashery.com

The old domain will still get you to the site until the registration expires near the end of this year.

#Foamsmithing #LARP

Foamdom is now The Whackerdashery and the docs site has been renamed to Whackipedia.

www.whackerdashery.com

wiki.whackerdashery.com

The old domain will still get you to the site until the registration expires near the end of this year.

#Foamsmithing #LARP

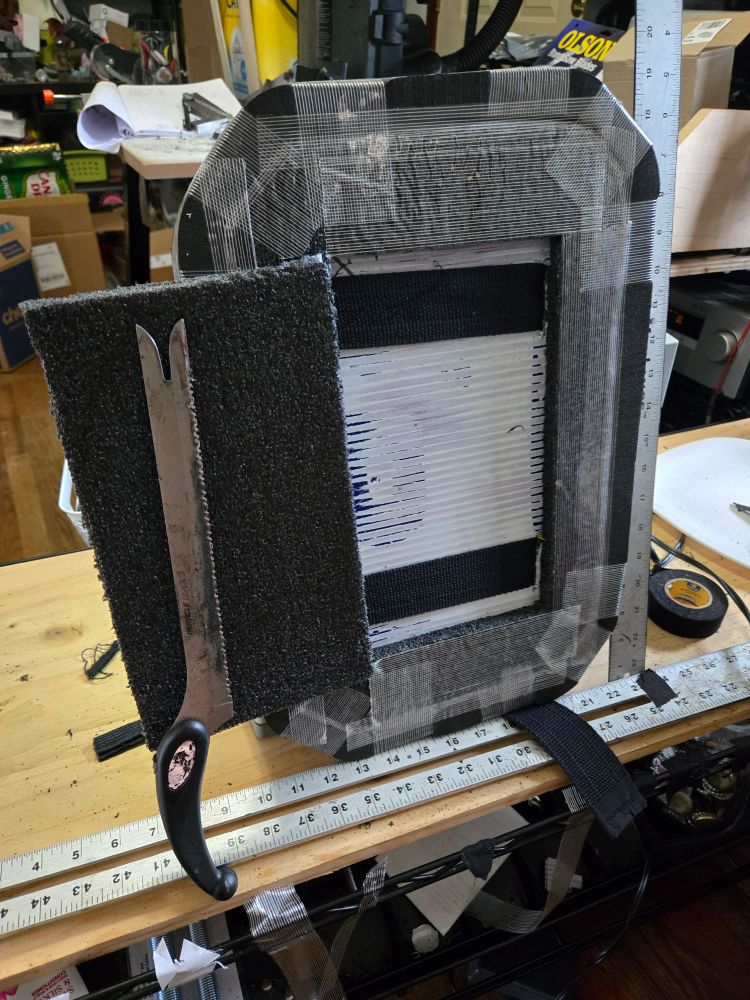

2# XLPE with 4# biscuits on both ends. NBR foundation, open cell point. 14mm*10mm carbon core (polished, unpainted, 3k twill finish).

Spear-level flex, handles one handed well, flies very straight, super easy to use.

2# XLPE with 4# biscuits on both ends. NBR foundation, open cell point. 14mm*10mm carbon core (polished, unpainted, 3k twill finish).

Spear-level flex, handles one handed well, flies very straight, super easy to use.

Looks "ok", but I know I can do a better tape layup next time.

Wasn't originally supposed to be responsible for the cover on this one, so it's just some scrap fabric while I'm test driving.

Looks "ok", but I know I can do a better tape layup next time.

Wasn't originally supposed to be responsible for the cover on this one, so it's just some scrap fabric while I'm test driving.

docs.foamdom.com/materials/co...

Also took measurements of all of the sizes I've tested so far, data in image.

docs.foamdom.com/materials/co...

Also took measurements of all of the sizes I've tested so far, data in image.

Bent and split/splayed PVC, 1/4" wide zip tie woven between splayed ends and 3 holes in coroplast in a figure 8. Coroplast is 2 perpendicular layers from 18x24 yard signs.

Will still be layering foam and filling voids with adhesive.

Bent and split/splayed PVC, 1/4" wide zip tie woven between splayed ends and 3 holes in coroplast in a figure 8. Coroplast is 2 perpendicular layers from 18x24 yard signs.

Will still be layering foam and filling voids with adhesive.

Finding out that I need to make the tubes oversize and then trim them afterwards if I want clean faces, but this is already doing pretty well for a trial run.

Now I need another heat gun...

Finding out that I need to make the tubes oversize and then trim them afterwards if I want clean faces, but this is already doing pretty well for a trial run.

Now I need another heat gun...

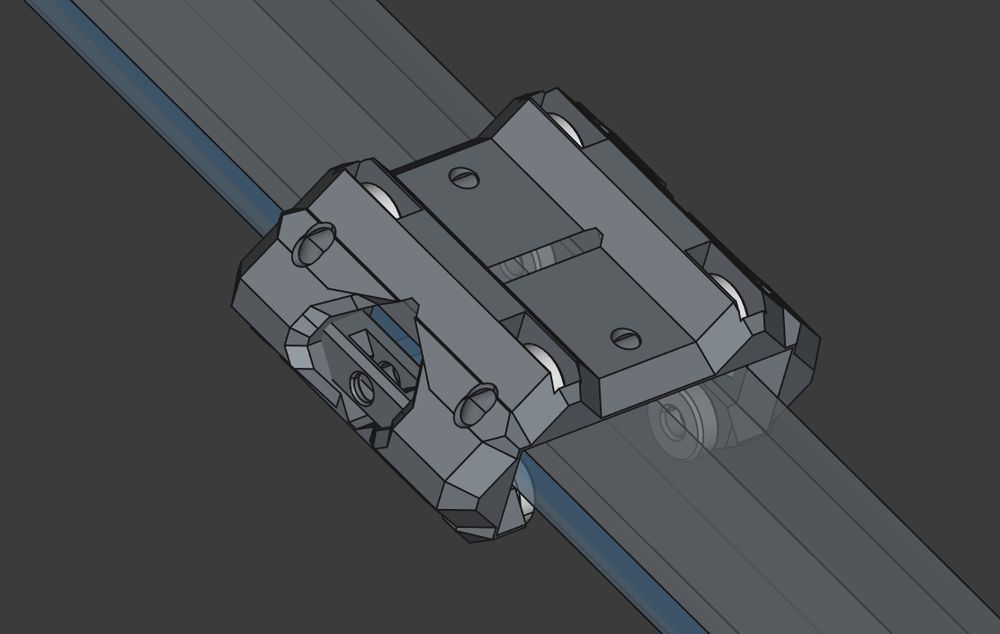

Just received and distributed the first 16mm*2m batch from the supplier. The tubes looked great, were well under flex tolerances, and went so fast at $35 each that I had to place another order within a day of them arriving.

More details and supplier link in replies.

Just received and distributed the first 16mm*2m batch from the supplier. The tubes looked great, were well under flex tolerances, and went so fast at $35 each that I had to place another order within a day of them arriving.

More details and supplier link in replies.

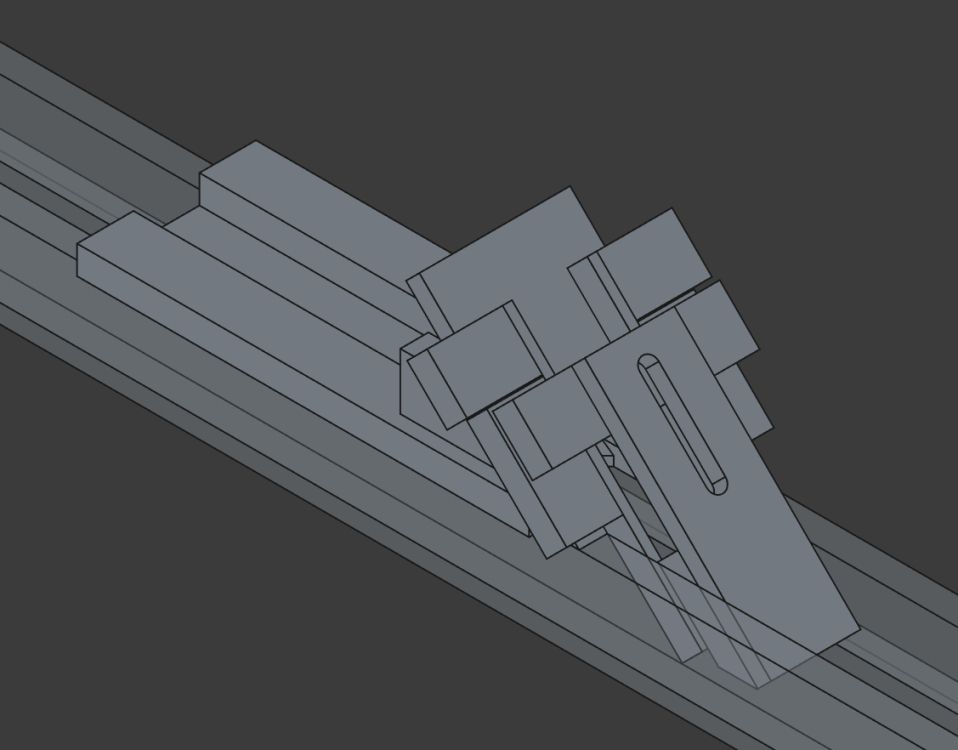

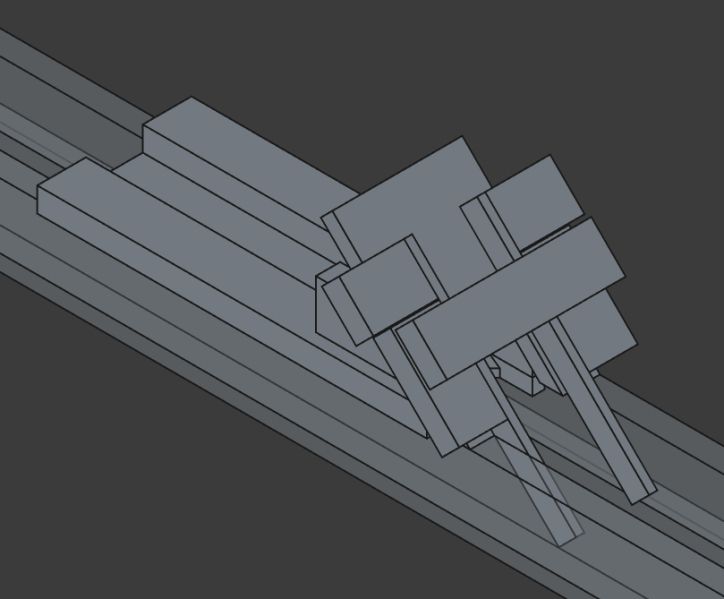

- Will just be securing the heat gun with stiff wire, threaded through holes on those braces.

- Won't matter if it rotates and the handle goes to the side.

- Elongated the ramp to protect the foam from getting heated early.

- Will just be securing the heat gun with stiff wire, threaded through holes on those braces.

- Won't matter if it rotates and the handle goes to the side.

- Elongated the ramp to protect the foam from getting heated early.

- brings the foam strips together and applies even pressure

- adjusts via sliding up and down on bolt using channel

- tighten wing nut on bolt to fix in place

- brings the foam strips together and applies even pressure

- adjusts via sliding up and down on bolt using channel

- tighten wing nut on bolt to fix in place

- 2nd foam strip is threaded between this and ramp

- clamps guide arms in place

- acts as mounting point for bond plate

- bolts stick out of standoffs with springs on them, wingnuts to adjust tightness

- 2nd foam strip is threaded between this and ramp

- clamps guide arms in place

- acts as mounting point for bond plate

- bolts stick out of standoffs with springs on them, wingnuts to adjust tightness