Industrial decarb, clean tech supply chains, energy for development

Chemical/energy engineer

Science is cool!!

Dems Alicia Johnson and Peter Hubbard beat incumbent Republicans Tim Echols and Fitz Johnson

Utilities funded 87% of F. Johnson's & 61% Echols' campaigns

They spent 12x as much as A. Johnson and Hubbard

Dems Alicia Johnson and Peter Hubbard beat incumbent Republicans Tim Echols and Fitz Johnson

Utilities funded 87% of F. Johnson's & 61% Echols' campaigns

They spent 12x as much as A. Johnson and Hubbard

- LiDAR

- Self-driving cars

- LASIK

- Breaking up kidney stones

- Photolithography & chip-making

- LiDAR

- Self-driving cars

- LASIK

- Breaking up kidney stones

- Photolithography & chip-making

But it's not NdPr used in permanent magnets so nobody cares!

But it's not NdPr used in permanent magnets so nobody cares!

It’s actually more like building a chemical plant next door

Note that carbon capture uses so much energy that it needs its own source of electricity (the cogeneration plant)

It’s actually more like building a chemical plant next door

Note that carbon capture uses so much energy that it needs its own source of electricity (the cogeneration plant)

Also materials/mechanical/chemical engineers to do rigorous quality tests and certify the product as industrial grade

Also materials/mechanical/chemical engineers to do rigorous quality tests and certify the product as industrial grade

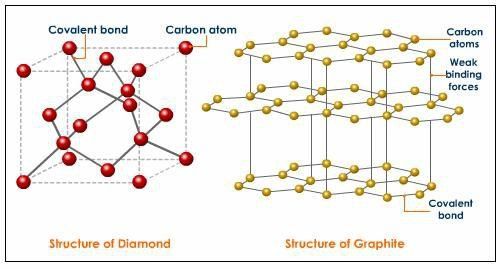

Crystal structure matters for the same reason why diamond and graphite/pencil led are both carbon but have such different properties

Crystal structure matters for the same reason why diamond and graphite/pencil led are both carbon but have such different properties

Heating to ~1000°C, just below the melting point, fuses the powder particles while keeping the bulk shape.

Heating to ~1000°C, just below the melting point, fuses the powder particles while keeping the bulk shape.

Gas compresses the powder equally on all sides while a magnetic field of 1~2 Tesla (100~200x stronger than a kitchen magnet) which makes the metal more magnetic

Gas compresses the powder equally on all sides while a magnetic field of 1~2 Tesla (100~200x stronger than a kitchen magnet) which makes the metal more magnetic

Then, also under inert gas to not react with oxygen, you shoot pulses of super compressed gas at the coarse powder to get finer, µm-sized bits.

Then, also under inert gas to not react with oxygen, you shoot pulses of super compressed gas at the coarse powder to get finer, µm-sized bits.

By carefully adding H2, the alloy gets brittled. Kinda like how water can crack rock from the inside when it freezes and expands.

By carefully adding H2, the alloy gets brittled. Kinda like how water can crack rock from the inside when it freezes and expands.

Except rare earth magnets need *extremely* high purities. Oxygen in the atmosphere is very reactive with metals (think rust), so melting happens under inert gas in a vacuum induction furnace

Except rare earth magnets need *extremely* high purities. Oxygen in the atmosphere is very reactive with metals (think rust), so melting happens under inert gas in a vacuum induction furnace

How do we actually make the solar cells, rare earth magnets, and high-strength alloys used in next-gen tech?

How do we actually make the solar cells, rare earth magnets, and high-strength alloys used in next-gen tech?

They say 50 Mtpy CCUS capacity in 2025. So 5% of 50 Mtpy = 2.5 Mtpy. Or ~1% of all CO2 used today.

So that’s an upper bound I guess using NZE and 2030 numbers as proxy. :)

www.iea.org/commentaries...

They say 50 Mtpy CCUS capacity in 2025. So 5% of 50 Mtpy = 2.5 Mtpy. Or ~1% of all CO2 used today.

So that’s an upper bound I guess using NZE and 2030 numbers as proxy. :)

www.iea.org/commentaries...

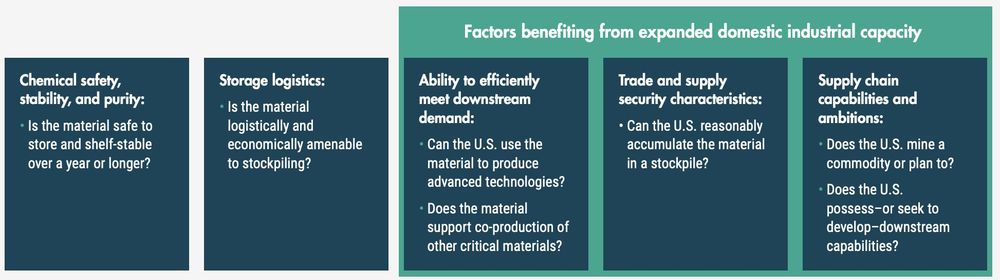

GaCl4 is a corrosive, highly toxic gas

Ga(CH3)3 is pyrophoric AKA it spontaneously combusts if exposed to air!

So stockpiling isn't just piles of rock in a warehouse!

GaCl4 is a corrosive, highly toxic gas

Ga(CH3)3 is pyrophoric AKA it spontaneously combusts if exposed to air!

So stockpiling isn't just piles of rock in a warehouse!

China makes 98% of the world’s low-purity Ga and banned exports to the US in Dec 2024. We obtain Ga only as a byproduct of processing other minerals and in low, borderline uneconomical amts

China makes 98% of the world’s low-purity Ga and banned exports to the US in Dec 2024. We obtain Ga only as a byproduct of processing other minerals and in low, borderline uneconomical amts

- Does US industry use the material? Make the material?

- How import-dependent is the US?

- Will the material degrade or become contaminated?

- Is the material safe to store?

- Does US industry use the material? Make the material?

- How import-dependent is the US?

- Will the material degrade or become contaminated?

- Is the material safe to store?

Importantly, I properly cover the *entire* process, from feedstock to fertilizer.

Importantly, I properly cover the *entire* process, from feedstock to fertilizer.

But even fertilizer made from imported nat gas is too expensive. SSA only has one option: tap into more domestic nat gas deposits

But even fertilizer made from imported nat gas is too expensive. SSA only has one option: tap into more domestic nat gas deposits

In my new study I provide much-needed cost estimates of green fertilizer made in SSA

The result? Even <$1/kg green H2 wouldn't make green fertilizer affordable🧵 www.breakthroughjournal.org/p/sub-sahara...

In my new study I provide much-needed cost estimates of green fertilizer made in SSA

The result? Even <$1/kg green H2 wouldn't make green fertilizer affordable🧵 www.breakthroughjournal.org/p/sub-sahara...