Reid; bazelcon edition

@arrdem.com

Proprietor https://tirefireind.us. Mostly reformed shitposter. Cat dad of two. If you were looking for someone it was the other guy.

"I will support [the president] invading my constituency if my opponent wins"

sulla dot jpeg

sulla dot jpeg

November 4, 2025 at 10:53 PM

"I will support [the president] invading my constituency if my opponent wins"

sulla dot jpeg

sulla dot jpeg

Behold, part of the #Python bullshit I've been working on for the last several months!

I've been slowly working up an implementation of `uv install` under #Bazel... using only Bazel. This is important because it lets Python apps built with Bazel do crossbuilds (eg build on your mac to prod Linux).

I've been slowly working up an implementation of `uv install` under #Bazel... using only Bazel. This is important because it lets Python apps built with Bazel do crossbuilds (eg build on your mac to prod Linux).

![Got the basic and most needed case of Python marker dependencies working!

In this case cryptography uses cffi if the Python implementation isn't PyPy which doesn't support cffi. This is implemented by creating a decide_marker rule named with a shasum of the marker condition string so that markers can be reused, and then the d41b92cd cycle group (which is the implementation of cryptography) depends on cffi only if the marker rule is true at configuration time.

@pip//cryptography/BUILD

alias(

name = "cryptography",

actual = "//private/sccs:d41b92cd",

visibility = ["//visibility:public"],

)

@pip//private/markers/BUILD

decide_marker(

name = "aa6882d8",

marker = "platform_python_implementation != 'PyPy'",

visibility = ["//private:__subpackages__"],

)

@pip//private/sccs/BUILD

# A placeholder library which allows us to select to nothing

py_library(

name = "empty",

srcs = [],

imports = [],

visibility = ["//visibility:private"]

)

# All of the markers under which d41b92cd depends on cffi

selects.config_setting_group(

name = "_maybe_d41b92cd_cffi",

match_any = ["//private/markers:aa6882d8"],

visibility = ["//visibility:private"],

)

# Depend on cffi of any of the d41b92cd markers are active

alias(

name = "_d41b92cd_cffi",

actual = select({

":_maybe_d41b92cd_cffi": "//cffi",

"//conditions:default": ":empty",

}),

visibility = ["//visibility:private"],

)

py_library(

name = "d41b92cd",

deps = [

"@whl_install__pypi__airflow__cryptography//:install",

":_d41b92cd_cffi"

],

visibility = ["//:__subpackages__"],

)](https://cdn.bsky.app/img/feed_thumbnail/plain/did:plc:izyoicsqthvug3v65qkmaops/bafkreibljic7ho2yyb4dnji6vskzqzgz7gmlp4nnrgvvypp3nbbs4wkhvu@jpeg)

November 4, 2025 at 7:04 AM

Starting to think they may be codependent

November 4, 2025 at 12:10 AM

Starting to think they may be codependent

After some shopping, this seems like the initial parts list. Could punt on the stock even.

November 3, 2025 at 6:29 AM

After some shopping, this seems like the initial parts list. Could punt on the stock even.

I think they missed me

November 1, 2025 at 3:58 PM

I think they missed me

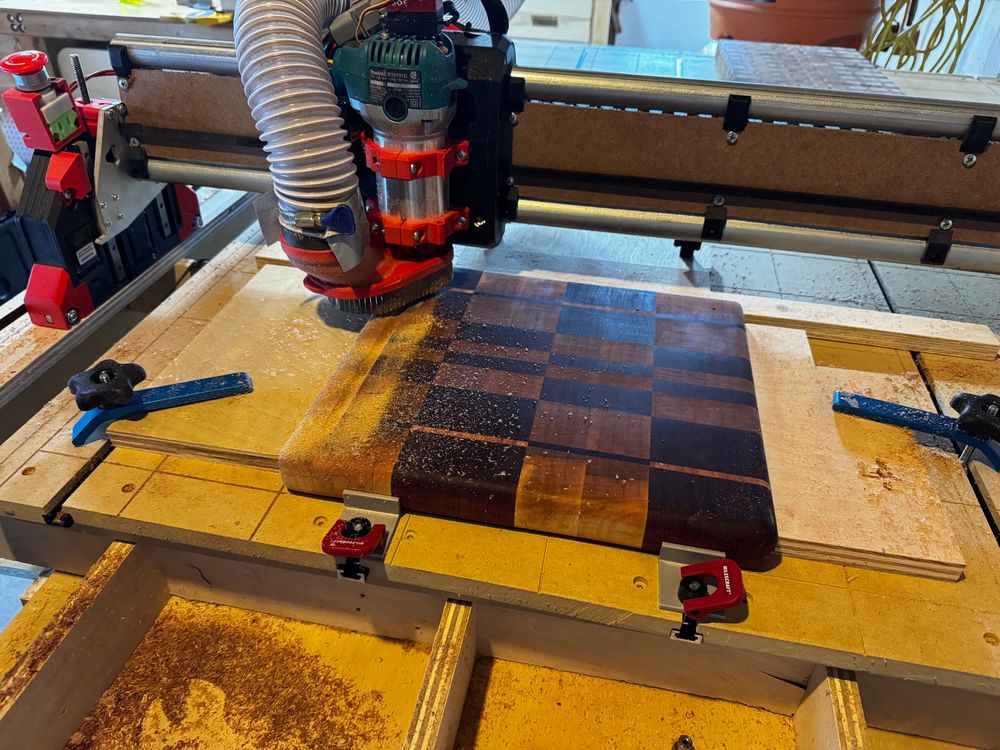

Gonna be honest dawg I spent six months building this thing and it’s better at wood than I’ll ever be. It’s nice to drink beer and wait for the machine to do its thing. Just moves the creativity doesn’t remove it.

October 27, 2025 at 4:06 AM

Gonna be honest dawg I spent six months building this thing and it’s better at wood than I’ll ever be. It’s nice to drink beer and wait for the machine to do its thing. Just moves the creativity doesn’t remove it.

I’m gonna get so much mileage out of this one. Also need a krompotkin that’s just laser eyes bread

October 27, 2025 at 2:02 AM

I’m gonna get so much mileage out of this one. Also need a krompotkin that’s just laser eyes bread

me @ computers today

October 23, 2025 at 6:23 PM

me @ computers today

I live for this shit.

October 23, 2025 at 4:01 AM

I live for this shit.

Which brings me, a little over a year later and mere days before the 1st anniversary, to a finished product.

October 23, 2025 at 4:01 AM

Which brings me, a little over a year later and mere days before the 1st anniversary, to a finished product.

Adding juice grooves to cutting boards is something woodworkers hate doing because it’s high potential for damaging the board. James thought I was nuts to trust the machine. In his defense it did take a couple tries, but we did ultimately succeed in carving the board as desired.

October 23, 2025 at 4:01 AM

Adding juice grooves to cutting boards is something woodworkers hate doing because it’s high potential for damaging the board. James thought I was nuts to trust the machine. In his defense it did take a couple tries, but we did ultimately succeed in carving the board as desired.

That board has since made huge progress that’s long been blocked on flattening through sanding, rounding and oiling.

October 23, 2025 at 4:01 AM

That board has since made huge progress that’s long been blocked on flattening through sanding, rounding and oiling.

That success in hand and about six months after we started in on building the lowrider, we finally milled the slab that started all this. To a near flawless flat on the first try.

October 23, 2025 at 4:01 AM

That success in hand and about six months after we started in on building the lowrider, we finally milled the slab that started all this. To a near flawless flat on the first try.

This weekend we had the first big successes with the machine — using it to work on something other than itself. Specifically, flattening cutting boards. The thing that got us into this in the first place. This is one of James’ we used for testing.

October 23, 2025 at 4:01 AM

This weekend we had the first big successes with the machine — using it to work on something other than itself. Specifically, flattening cutting boards. The thing that got us into this in the first place. This is one of James’ we used for testing.

That first milestone complete we were able to use the machine to flatten its own tabletop to plane (which is the second thing you’re supposed to use it for) and @tsothoga.bsky.social worked up some refinements to the tabletop adding work holding track and more expendable spoil boards.

October 23, 2025 at 4:01 AM

That first milestone complete we were able to use the machine to flatten its own tabletop to plane (which is the second thing you’re supposed to use it for) and @tsothoga.bsky.social worked up some refinements to the tabletop adding work holding track and more expendable spoil boards.

The lowrider machine passed its first big function test a few weeks back when it succeeded in the first thing you’re supposed to use it for - carving out the stiffening boards for the lowrider’s core frame

October 23, 2025 at 4:01 AM

The lowrider machine passed its first big function test a few weeks back when it succeeded in the first thing you’re supposed to use it for - carving out the stiffening boards for the lowrider’s core frame

The electromechanical parts mostly complete it was @tsothoga.bsky.social’s turn and we banged first a table and then a significantly improved table to mount the robot on.

October 23, 2025 at 4:01 AM

The electromechanical parts mostly complete it was @tsothoga.bsky.social’s turn and we banged first a table and then a significantly improved table to mount the robot on.

Assembly and some initial test cuts took a while, but the v1e docs were super easy to follow and the robot itself mostly shook and baked.

October 23, 2025 at 4:01 AM

Assembly and some initial test cuts took a while, but the v1e docs were super easy to follow and the robot itself mostly shook and baked.

This is however the entire frame you’d need to build some sort of XY movement machine. And then you still have to actuate it manually. So I talked @tsothoga.bsky.social into agreeing to let me put a robot table in his shop, ordered the parts kit and fired up the 3d printers.

October 23, 2025 at 4:01 AM

This is however the entire frame you’d need to build some sort of XY movement machine. And then you still have to actuate it manually. So I talked @tsothoga.bsky.social into agreeing to let me put a robot table in his shop, ordered the parts kit and fired up the 3d printers.

I’d just finished scratch building a small fleet of 3d printers and @directxman12.dev had mentioned the @v1engineering.bsky.social Lowrider CNC machine. And I’d gotten to see one in person at RMRF where I was impressed with the sheer simplicity of the design.

October 23, 2025 at 4:01 AM

I’d just finished scratch building a small fleet of 3d printers and @directxman12.dev had mentioned the @v1engineering.bsky.social Lowrider CNC machine. And I’d gotten to see one in person at RMRF where I was impressed with the sheer simplicity of the design.

The fix itself was straightforward enough although frustrating. Carve out the damaged wood and glue some new wood in. But clearly the flattening solution we had wasn’t nearly adequate to the task at hand.

October 23, 2025 at 4:01 AM

The fix itself was straightforward enough although frustrating. Carve out the damaged wood and glue some new wood in. But clearly the flattening solution we had wasn’t nearly adequate to the task at hand.

Unfortunately the aforementioned sled sucked, and not only did the board come out textured from router bite and vibration rather than flat, the router took a bite out of the board. I wasn’t enthused.

October 23, 2025 at 4:01 AM

Unfortunately the aforementioned sled sucked, and not only did the board come out textured from router bite and vibration rather than flat, the router took a bite out of the board. I wasn’t enthused.