3 for 3. Now lets hope that one of the three is serviceable. What am I going to do with three lidar units you might ask...? Well that is a great question.

In the words of the wise Tevye, "I don't know"...

3 for 3. Now lets hope that one of the three is serviceable. What am I going to do with three lidar units you might ask...? Well that is a great question.

In the words of the wise Tevye, "I don't know"...

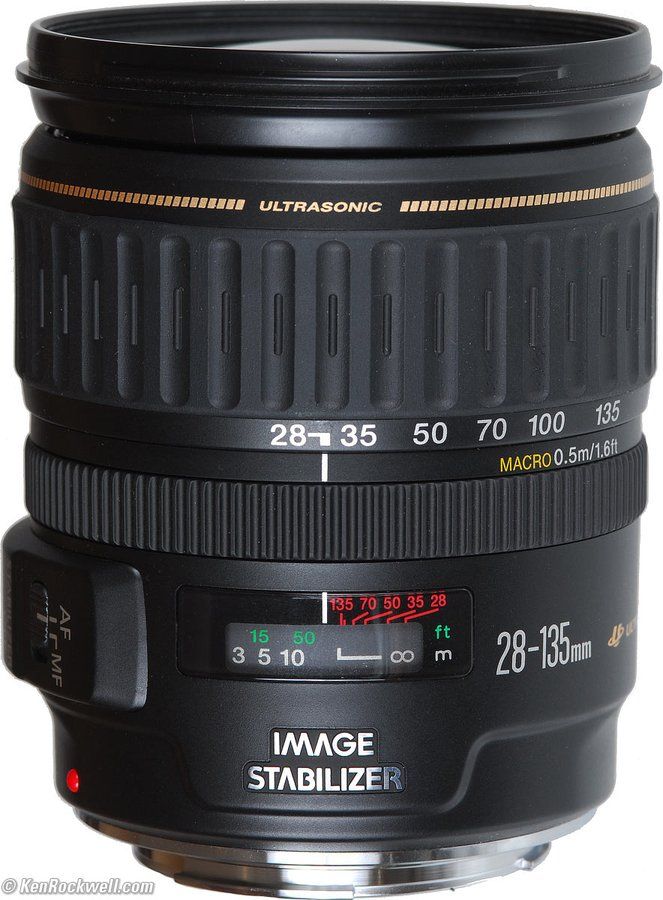

First up, putting the mount ring on the lens adaptor. It was ~ø1mm too big & needed a hole for the lens release button.

3D printed a shim & used my 60W fiber laser to cut through the ~5mm thick AL to expose the lens release button.

First up, putting the mount ring on the lens adaptor. It was ~ø1mm too big & needed a hole for the lens release button.

3D printed a shim & used my 60W fiber laser to cut through the ~5mm thick AL to expose the lens release button.

@ubermeisters.bsky.social

@gregsaunier.bsky.social

@ubermeisters.bsky.social

@gregsaunier.bsky.social

In this method, I used a cleaning pass to remove oxides off the surface. That produced a very interesting stippling effect around the cut.

In this method, I used a cleaning pass to remove oxides off the surface. That produced a very interesting stippling effect around the cut.

Will be used indoors under very controlled conditions. I want to see how it will work as a digital microscope lens when paired with a Pinefeat adaptor to the RasPi High Quality Camera sensor.

Will be used indoors under very controlled conditions. I want to see how it will work as a digital microscope lens when paired with a Pinefeat adaptor to the RasPi High Quality Camera sensor.

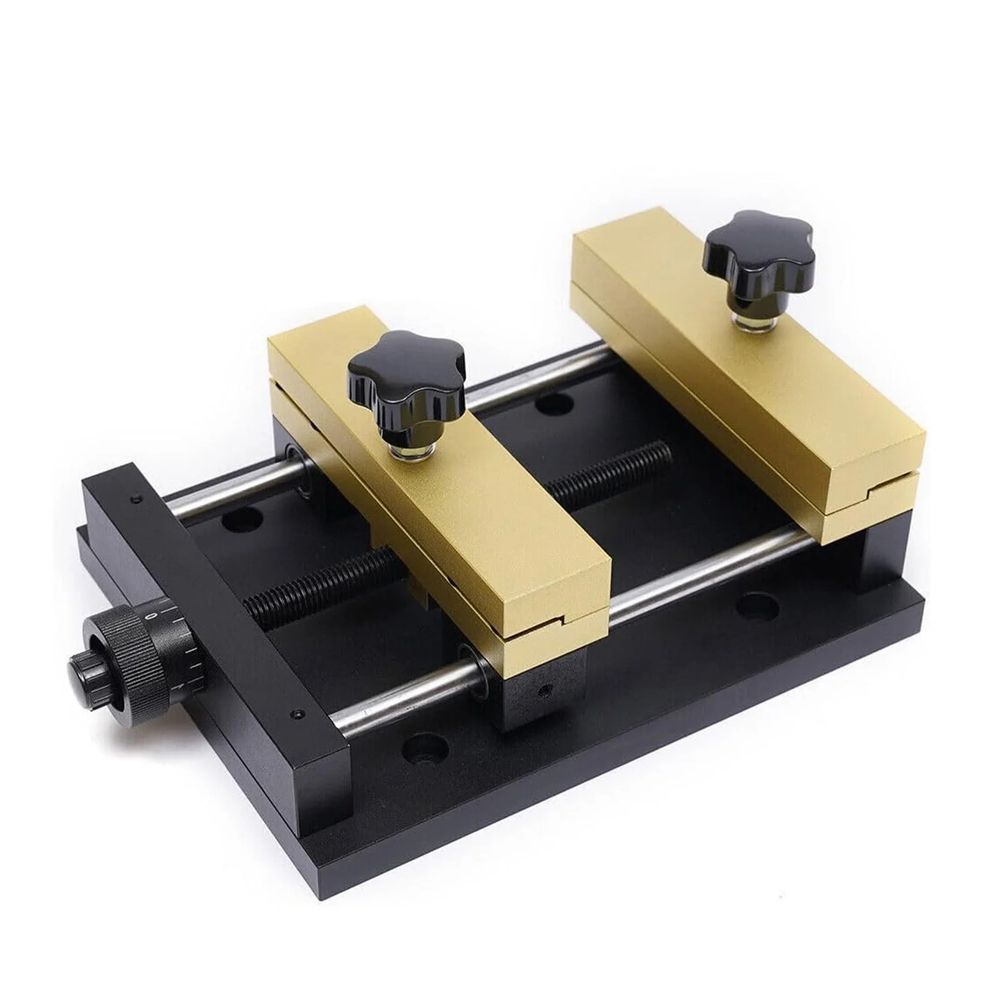

The most visible tool is the one from ComMarker itself. Here is the link to that: commarker.com/product/comm...

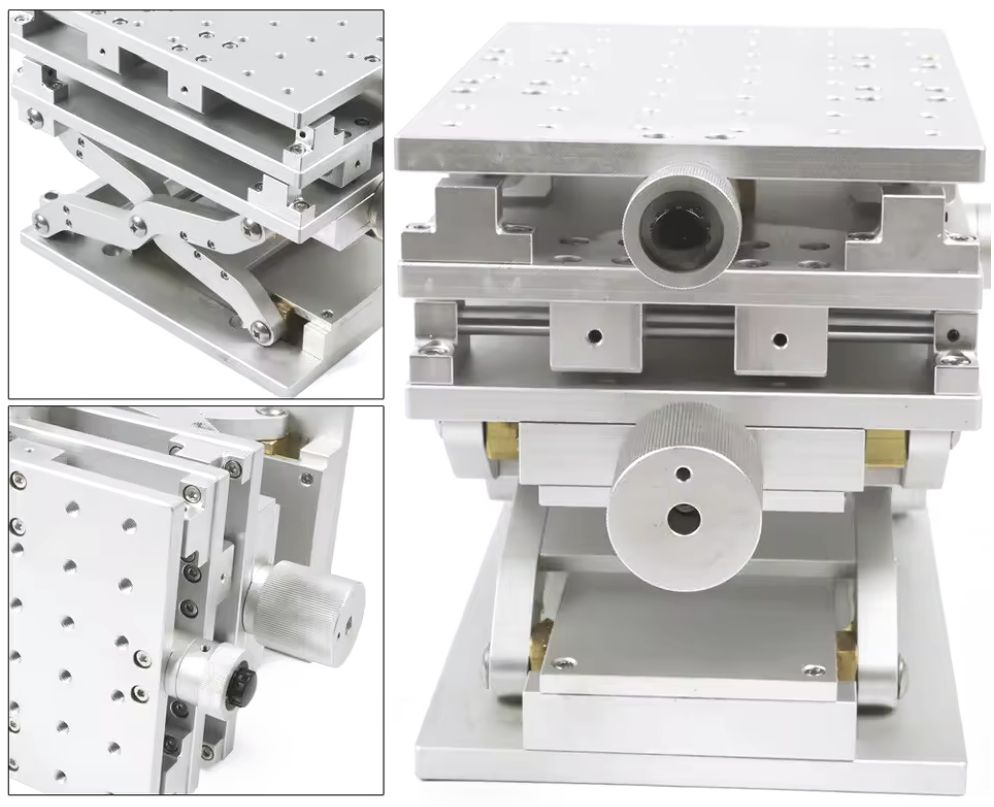

The second one is an X, Y, Z table that I got from Aliexpress:

www.aliexpress.us/item/3256807...

The most visible tool is the one from ComMarker itself. Here is the link to that: commarker.com/product/comm...

The second one is an X, Y, Z table that I got from Aliexpress:

www.aliexpress.us/item/3256807...

ø9.4mm - 45 teeth

ø3.4mm - 15 teeth

I was also able to remove them from the frame and confirmed that they mesh.

I still need to make some minor changes on the process, but custom gears in about 30min.

ø9.4mm - 45 teeth

ø3.4mm - 15 teeth

I was also able to remove them from the frame and confirmed that they mesh.

I still need to make some minor changes on the process, but custom gears in about 30min.