So, the new idea is just have 2 independent barrels per fret, each with it's own servo, and 4 combos. It'll double the servo count and complicate the controls, but it will cleanly depress springs.

So, the new idea is just have 2 independent barrels per fret, each with it's own servo, and 4 combos. It'll double the servo count and complicate the controls, but it will cleanly depress springs.

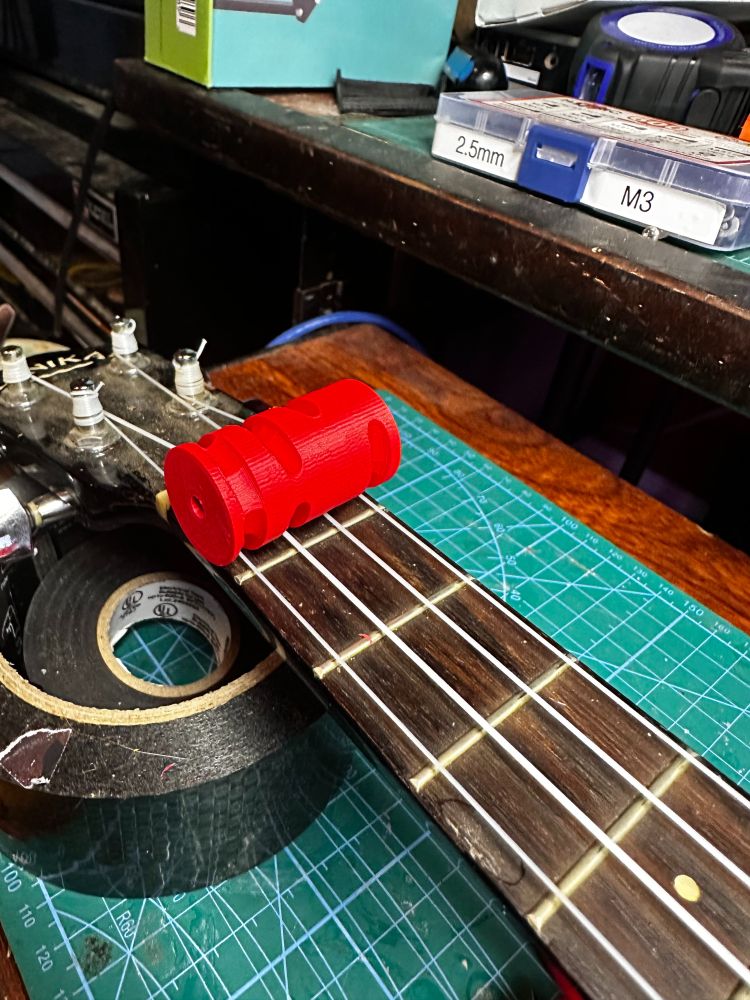

It’s a mess but it’s mechanically able to play a note. #3dprinting #adafruit

It’s a mess but it’s mechanically able to play a note. #3dprinting #adafruit

It binds to the rail better, and is overall slimmer #3DPrinting

It binds to the rail better, and is overall slimmer #3DPrinting